Navigating Sustainability in Lubricants:

Insights from the Inaugural Forum

A Comprehensive Overview of Key Presentations and Sustainable Practices in the Lubricants Industry

Introduction

On the 29th and 30th of November, the inaugural Lubricants Sustainability Forum took place at the Hotel DoubleTree by Hilton Berlin Kudamm in Berlin. Simultaneously, the event coincided with the second editions of the Sustainable Aviation Fuels Forum and the Sustainable Maritime Fuels Forum, all seamlessly organized and coordinated by InventU.

The first edition of the forum saw the participation of 45 individuals, predominantly from European countries. The event featured a total of 15 presentations, with a primary focus on contributions from lubricant ingredient suppliers and lubricant formulators.

Presentations

The inaugural session commenced with Mr. Otto Linher, a senior expert at the European Commission overseeing the implementation of the EU Chemicals Strategy for Sustainability. He articulated a vision aimed at reshaping the EU's economy for a sustainable future, emphasizing a pivotal short-term goal of achieving zero pollution for a toxic-free environment.

The Chemicals Strategy for sustainability, devised in October 2020, is structured around five key pillars: Innovation, competitiveness, and recovery; Strengthening legislation for better protection; Simplification and coherence; Knowledge and science; and Global considerations. Notably, the current Commission has already taken significant strides, introducing new hazard classes through the CLP revision, effective from December 22nd, 2022. These revisions specifically address concerns related to endocrine disruptors, PBT/vPvB/PMT/vPvM, and have brought clarity to rules governing mixtures, complex substances, and simplified labeling.

While ongoing discussions within the present Commission center around the Reach revision, no formal proposal will be presented during the current mandate. The proposal has been deferred for consideration by the next Commission nomination. Key topics for the upcoming proposal include discussions on polymers registration and the potential to cancel registration numbers in cases of persistent non-compliance. Additionally, various initiatives currently under deliberation aim to offer tools for streamlining the regulatory process and exploring alternative solutions through comprehensive substitution planning studies.

The second presentation of the day was led by Hans Gerdes, Head of Business Development at Metall-Chemie, who shared his distinctive perspective on sustainability as an additive supplier with the audience. Throughout his presentation, Gerdes expressed notable criticism toward the European Chemicals Agency (ECHA) and highlighted deficiencies in administrative processes. As an additive producer, Gerdes underscored the considerable impact of regulatory limitations on their operations. However, he also shed light on the industry's efforts to present regulatory-compliant alternatives, particularly for substances like polyfluoroalkyl substances (PFAS).

In addressing the challenges posed by regulations, Gerdes proposed a dialkyl-phosphonate as a viable alternative. This compound, boasting 90% renewability and a phosphorous content of 5 to 6%, demonstrated its effectiveness as an extreme pressure (EP) additive when compared to various thiophosphates in a 4-ball anti-wear test.

To underscore the gravity of regulatory constraints on additives, Gerdes presented market data from reputable sources such as BAFA, Kline, and Fuchs. His analysis concluded that despite an anticipated 10% contraction in the German lubricant market due to the disruptive influence of electric vehicle (EV) penetration and shared mobility development, the consumption of additives in lubricants is projected to surge by 18% in 2030.

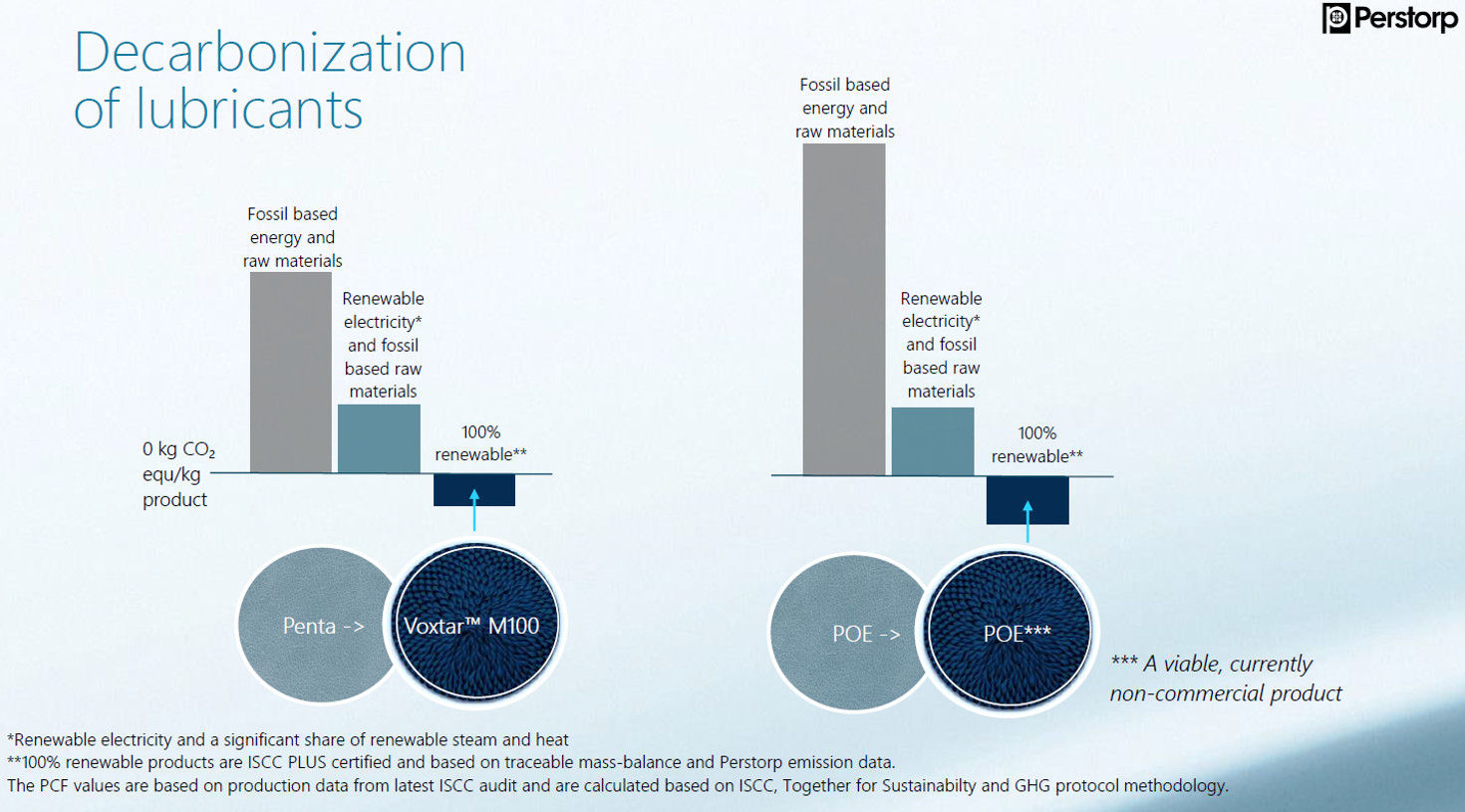

Following the morning break, which provided an excellent opportunity for parallel discussions and networking among participants, Ms. Elisa Swanson-Parbäck, Business Development Director for Sustainable Lubricants at Perstorp, commenced her presentation on the carbon footprint from the perspective of a raw material producer. Using data from the Perstorp database, she illustrated that the chemical sector ranks among the lowest in terms of companies with established targets concerning the Science Based Targets initiative (SBTi).

Elisa highlighted the challenges in calculating the carbon footprint of a product from the viewpoint of a raw materials producer. She emphasized the need for a meticulous breakdown of information, advocating for individual case analyses to understand the significance of each parameter in a Life Cycle Assessment (LCA). Elisa coined this approach as "The mixer board of sustainable solutions." Throughout her presentation, she underscored the critical importance of data collection and classification, distinguishing between primary and secondary data.

In emphasizing transparency, Elisa stressed the importance of disclosing the origin of data and the methods employed in calculations. Perstorp, in line with this commitment, opts for external and reference accreditation, such as ISCC Plus.

Concluding her presentation, Elisa demonstrated the feasibility of decarbonizing raw materials for lubricants today. She presented examples of an alcohol and a polyolester, both exhibiting negative carbon footprint values (kg CO2 eq/kg product), showcasing tangible steps toward sustainable practices in the raw materials production sector.

Mr. Wilhelm Rehbein, a Senior Manager in Application Technology at Lanxess, boasts over 35 years of expertise in formulating and maintaining metalworking and industrial lubricants. During his presentation, which centered on sustainable EP additives with a specific focus on metalworking applications, he enlightened the audience on the prospect of substituting medium chain chlorinated paraffins (MCCP) with sulfur carriers derived from renewable raw materials. Notably, some of these carriers are non-bioaccumulative and pose no toxicity to aquatic life.

Through the presentation, Mr. Rehbein shared findings from cutting and forming micro-tapping torque studies. The conclusive results indicated that sulfur carriers offer a viable alternative to MCCPs, showcasing a reduction in adhesive and abrasive wear. This insight not only underscores the potential environmental benefits of such substitutions but also highlights the advancements in sustainable practices within the realm of metalworking lubricants.

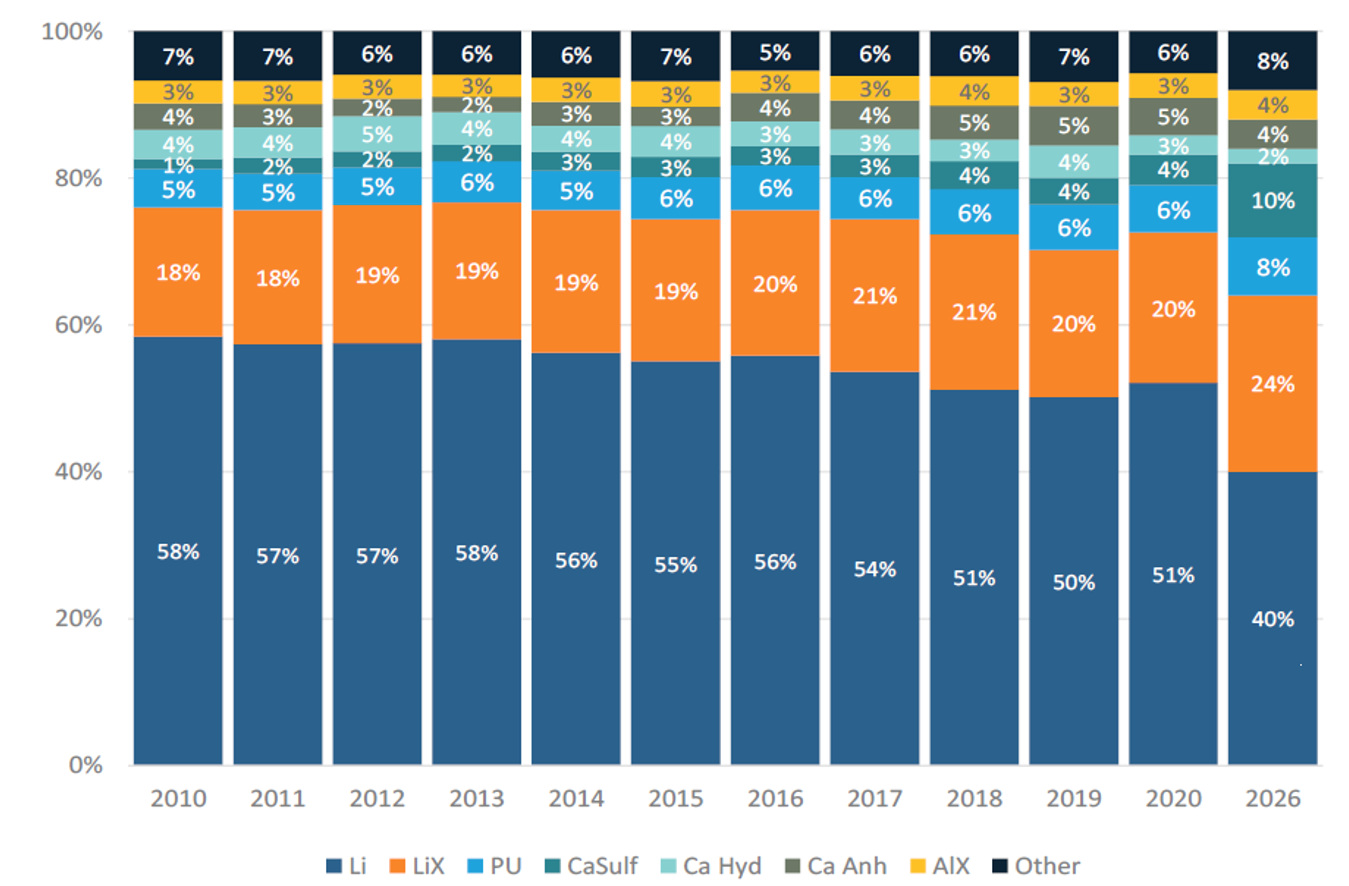

Mr. Terry Dicken, representing ELGI, provided valuable insights into anticipating future restrictions in grease applications, considering factors such as regulations, environmental sustainability, raw material availability, end-use demands, and the issue of greenwashing. Focusing on raw material constraints, he particularly highlighted concerns surrounding PFAS and Lithium. PFAS had previously been addressed by Metall-Chemie. The industry's well-acknowledged awareness of the limited availability of Lithium, a key component used as a thickener for greases and in battery production, was also emphasized. Notably, NLGI numbers indicate a significant decline in preference for Lithium, with a shift toward calcium, aluminum, and poly urea.

Global Industrial Grease Demand by Thickener

In conclusion, Terry highlighted ELGI's initiative to establish a sustainability consortium. This collaborative effort aims to bring together all stakeholders in the grease value chain, including manufacturers, distributors, raw material suppliers, end-users, test method suppliers, lubricant equipment manufacturers, as well as technical and trade institutes. The primary objective is to create a comprehensive framework for carbon footprint calculations, providing a unified and industry-wide reference for sustainability considerations in grease manufacturing and application.

Dr. Marcus Björling, an Associate Professor at Lulea Technical University in Sweden, presented a compelling proposition to the audience: adopting a strategy akin to the one employed in the alkyd paint industry for low Volatile Organic Compounds (VOC), but this time applied to water-based lubricants. As he delved into his discourse, Dr. Björling emphasized a noteworthy quote: "It is estimated that, at present, approximately 50% of all lubricants sold worldwide end up in the environment via total loss applications, volatility, spills, or accidents" (M. P. Schneider, Journal of the Science of Food and Agriculture, 2006). Additionally, he shared insights from McKinsey & Co, indicating that "World oil consumption in 2050 is expected to be 55% of today's level." This information underscored the urgency and relevance of exploring more environmentally friendly alternatives, aligning with the broader global shift toward sustainable practices in various industries.

Dr. Björling then suggests the use of glycerol-water blends, highlighting several advantages of glycerol: its widespread production and availability, cost-effectiveness, non-toxic nature, status as a by-product from bio-diesel production, water solubility offering new possibilities, fire resistance, and superlubricity. Notably, the viscosity of glycerol-water at 1 GPa is 4 Pas, compared to the viscosity of oil at 1 GPa, which is 2 106 Pas. This unique physical characteristic of the blend results in specific superlubricity behavior during the elastohydrodynamic stage.

The MTM (micro-tribometer) results, varying the SRR (sliding-rolling ratio) percentage, demonstrate a threefold reduction in the coefficient of friction in water blends with 5% to 20% water content compared to rapeseed oil. Additionally, there is evidence of a higher thickness film forming in water blends with 5% to 10% water content compared to rapeseed oil.

After a thorough evaluation of various aspects, Dr. Björling concludes that defining a new optimum is imperative. This involves striking a balance between performance, cost reduction, and improved sustainability. Such a compromise becomes necessary as impending legislation is expected to curtail products with lower sustainability, emphasizing the need for innovation and environmentally conscious solutions in lubricant formulations.

Dr. Kartik Pondichery, representing Anton Paar as a principal scientist and Product Manager, emphasized the pivotal role that lubricant tribology performance plays in sustainability for the entire audience. He presented impressive Stribek curves that spanned from high to low speeds in sliding velocity mode, illustrating the transition to the static regime point at very low speeds. Additionally, he underscored the significance of avoiding contaminants in lubricant systems during operation. This point was elucidated through sliding Stribek curves featuring different base oils with varying soot content percentages. The accompanying visuals included striking images of wear scars, vividly showcasing how soot hinders film formation on the surface, consequently increasing the wear scar diameter.

Building on this, Dr. Pondichery introduced new capabilities aligned with the latest technical Original Equipment Manufacturer (OEM) requirements. This encompassed testing greases for breakaway torque at -80°C, a condition commonly encountered in aviation. Furthermore, he explored combinations of torque and impedance data necessary for applications in Electric Vehicles (EVs). These insights demonstrated the ongoing advancements in lubrication technology, aligning with the evolving demands of various industries and emphasizing the importance of addressing tribological aspects for sustainable and efficient performance.

Dennis Eijdenberg, Technical Support Manager at Axel Christiernsson, centered his presentation on three key grease topics: the lithium paradoxes, vehicle electrification, and sustainability vision. Regarding lithium, it's noteworthy to highlight that in December 2021, ECHA’s Risk Assessment Committee (RAC) proposed a harmonized classification for lithium hydroxide, lithium carbonate, and lithium chloride. This proposal could potentially place lithium hydroxide on the Candidate List as a Substance of Very High Concern (SVHC). Additionally, ECHA suggested expanding the classification beyond LiOH, Li2CO3, and LiCl to include 34 compounds. The potential implementation of these changes indicates a plausible shift toward lithium hydroxide in due course.

Dennis then suggested to the audience anhydrous calcium as a viable alternative to lithium thickener, commonly used in environmentally acceptable lubricants (EALs) and Food Grade applications. This alternative thickener exhibits high water resistance, favorable low-temperature rheology, high shear stability, and strong adherence to surfaces.

In the context of vehicle electrification, it became evident that greases would play a crucial role. The absence of Original Equipment Manufacturer (OEM) specifications poses a significant challenge in designing greases to meet performance expectations. The advent of this new technology introduces unique requirements, such as balancing isolation versus conductivity and addressing low noise standards, demanding innovative testing methodologies.

Concluding his presentation, Dennis shared Axel's distinct perspective on selecting the sustainability level of a grease. For a loss lubrication system, the preference should be an Environmentally Acceptable Lubricant (EAL). In cases where it is not a loss lubrication application but involves substantial grease consumption, the choice should lean towards a low footprint grease. In scenarios where both factors are negative, the focus should shift to performance and energy efficiency. This simplified approach offers a groundbreaking way to analyze and classify different degrees of grease sustainability, recognizing that a more detailed assessment requires consideration of numerous nuances in the equation.

The final presentation of the day was delivered by Dr. Patrick Degen, Head of Innovation Management at Carl Bechem. He shared his latest work with the audience, focusing on the development of polymeric bio-based urea thickeners for lubricating greases. Dr. Degen demonstrated the feasibility of designing polymeric structures as thickeners to achieve a harmonious balance between performance and sustainability, embracing the concept of a fill-for-life approach, improved PCF (Performance Cost Factor), and a high bio-based carbon content.

In particular, Dr. Degen detailed the combination of various building blocks, including 1,5 Pentamethylendiisocyanate (PDI), 2,5-Bisaminomethylenfurane (BAMF), 1,5-Pentamethylendiamine (PDA), and 4,4’-Methylendiphenyldiisocyanate (MDA), in the creation of these innovative biobased thickeners. His work showcased the potential of such formulations to contribute to both enhanced lubricating grease performance and a more sustainable, bio-based approach.

The subsequent day, Mr. Andreas Dodos, a Chemical Engineer at Eldon’s and a member of the Board of Directors at ELGI, commenced his presentation by providing the audience with an overview of the historical perception of sustainability. He illustrated this with an iconic picture from the 1940s depicting bathers relaxing next to imposing industrial structures on Huntington Beach, Southern California. At that time, this juxtaposition was perceived as a symbol of prosperity and modernity. However, Mr. Dodos swiftly grounded us in reality by highlighting that, currently, fossil fuels stand as the most efficient means of obtaining energy (excluding nuclear).

After delving into the well-known context of decarbonization, predominantly led by Europe, Andreas introduced the concept of the carbon handprint. He emphasized that this metric holds more solidity than the carbon footprint, as it considers the effectiveness and durability of the lubricant throughout its application lifecycle (from cradle to grave). During this life cycle assessment (LCA) discussion, Andreas underscored the significance of Sustainable Development Goals (SDGs), with key focus areas being:

- 9th – Industry Innovation and Infrastructure

- Sustainable product design

- Use of raw materials

- Use of production methods

- Design of production equipment

- 12th – Responsible Production and Consumption

- Service life of products

- Classification & labeling of products

- Packaging considerations

- End-of-life considerations

- 7th – Affordable and Clean Energy

- Minimize frictional losses

- Renewable energy use in Scope 1 to 3 activities

- Avoided emissions

- Location

In conclusion, Andreas asserted that while the decarbonization of the lubricants sector is indeed feasible, innovation is the linchpin. He illustrated this point using the symbolism of a mammoth in a photo, underscoring the significance of adaptability to change – a crucial aspect for the sector's success in navigating the evolving landscape.

Dr. Boris Zhmud, representing Kata, presented to the audience the significance and viability of the circular economy in producing lubricant base oils. He elucidated the Kata business model, which revolves around transforming waste plastic into lubricating oils. In this scenario, the sustainability value stems from the raw material's origin, addressing a substantial global concern – ocean plastic pollution, which amounts to 176 kT per year.

Following that, Dr. Marcel Harhausen, Global Marine Business Development Manager at BASF, discussed net zero carbon footprint Polyisobutylenes (PIBs) derived from biogas feedstocks. The new PIBs, known as HR PIB, exhibit a chlorine content lower than 1 mg/kg, in stark contrast to the typical PIB's 135 mg/kg. The primary advantage lies in the prevention of corrosion initiation due to chlorine compounds. Subsequently, Dr. Harhausen elaborated on the advantages of using PIBs in comparison to Polyalphaolefins (PAOs).

Pierre Vanderkelen, the CEO of Fluitec NV, detailed the Fluitec business model – a blend of services and consulting designed to assist production companies in enhancing the maintenance of their lubricating fluids. Through fluid analysis and subsequent improvements facilitated by custom additive packages, Fluitec showcased its ability to significantly prolong the lifespan of fluids. In a compelling case study, they asserted that they successfully extended the life of a lubricant by an additional 10 years, resulting in estimated cost savings of $3.5 million and a reduction of 3000 metric tons of CO2 equivalent.

The event's conclusion was delivered by Mr. Tommi Järvinen, the Commercial Director at Avista Oil. He underscored the vital role of the re-refining business in the lubricant sector, emphasizing process and quality enhancements in products. Additionally, he highlighted the challenges associated with collecting used oil for reuse.

Conclusions

In reflecting on the Lubricants Sustainability Forum, it's evident that the event played a crucial role in fostering dialogue and awareness within the lubricants sector. The gathering provided a platform for industry leaders, experts, and professionals to share insights and address the pressing challenges of sustainability. From my perspective, three key takeaways stand out:

Firstly, the forum highlighted the industry's proactive response to regulatory changes. Presentations by experts like Mr. Otto Linher shed light on the EU's Chemicals Strategy, emphasizing the need for innovation and adaptation to meet ambitious sustainability goals. The industry's engagement with these regulatory challenges was palpable, showcasing a collective commitment to compliance and responsible practices.

Secondly, the event underscored the importance of collaboration across the lubricant value chain. Initiatives such as ELGI's sustainability consortium and discussions on alternative raw materials demonstrated a shared commitment to finding holistic solutions. The recognition that sustainability requires a concerted effort from manufacturers, distributors, end-users, and regulatory bodies is a positive step towards a more sustainable future for the sector.

Lastly, the diverse range of topics covered, from water-based lubricants to circular economy practices, showcased the industry's capacity for innovation. The forum served as a catalyst for exploring novel approaches, such as glycerol-water blends and polymeric bio-based urea thickeners. These innovations are not only essential for meeting sustainability targets but also for maintaining the industry's competitive edge in a rapidly evolving market.

In conclusion, the Lubricants Sustainability Forum proved to be a valuable and insightful event for the sector. It succeeded in bringing together key stakeholders, fostering collaboration, and stimulating innovative thinking. As the industry navigates the complexities of sustainability, forums like these play a pivotal role in shaping a future where lubricants not only meet stringent environmental standards but also drive positive change across the entire value chain.

Marc Alumà

Global Lubricant Business Unit Director in IQL

December 2023.