Major international organisms have as a common denominator that an environmental acceptable lubricant (EAL) should meet the following three principles:

- Biodegradability

- Non-toxic to aquatic organism

- Not bio-accumulating in the environment

It can also include renewability, but it is not necessarily required:

- Not required for European Ecolabel Lubricants from January 2019

- Minimum 25% required for European CEN (committee for standardization) definition of a bio-lubricant

- Minimum requirement defined by application for US Bio-Preferred Program (which is not required to be biodegradable)

- Minimum requirement defined for stainless steel greases (category A and B)

| European Eco-label Lubricants | Blue Angel (Bio-lubricants and hydraulics) |

Swedish Standard Greases | Swedish Standard Hydraulics | OSPAR HOCNF (Marine North-East Atlantic) |

VGP (Vessel General Permit) | CEN 16807:2016 |

|

|---|---|---|---|---|---|---|---|

| Biodegradability | Substances only | yes | yes | yes | yes | yes | Final product |

| Bioaccumulation | Substances only | yes | no | no | yes | yes | no |

| Aquatic toxicity | Substances and formulated products | yes | yes | yes | yes | yes | Final product |

| Minimum renewability content | Not required >25% to use bio-lubricant terminology | no | yes (A and B) | no | no | no | >25%; final product |

| Origin certified | Palm derivatives | no | no |

no | no | no | no |

| Limitations on specific chemicals | yes | yes | yes | yes | yes | yes | no |

| Technical requirements specified | OEM approved or technical standards | yes | yes (SS 155470) |

yes (SS 155434) |

no | yes | yes |

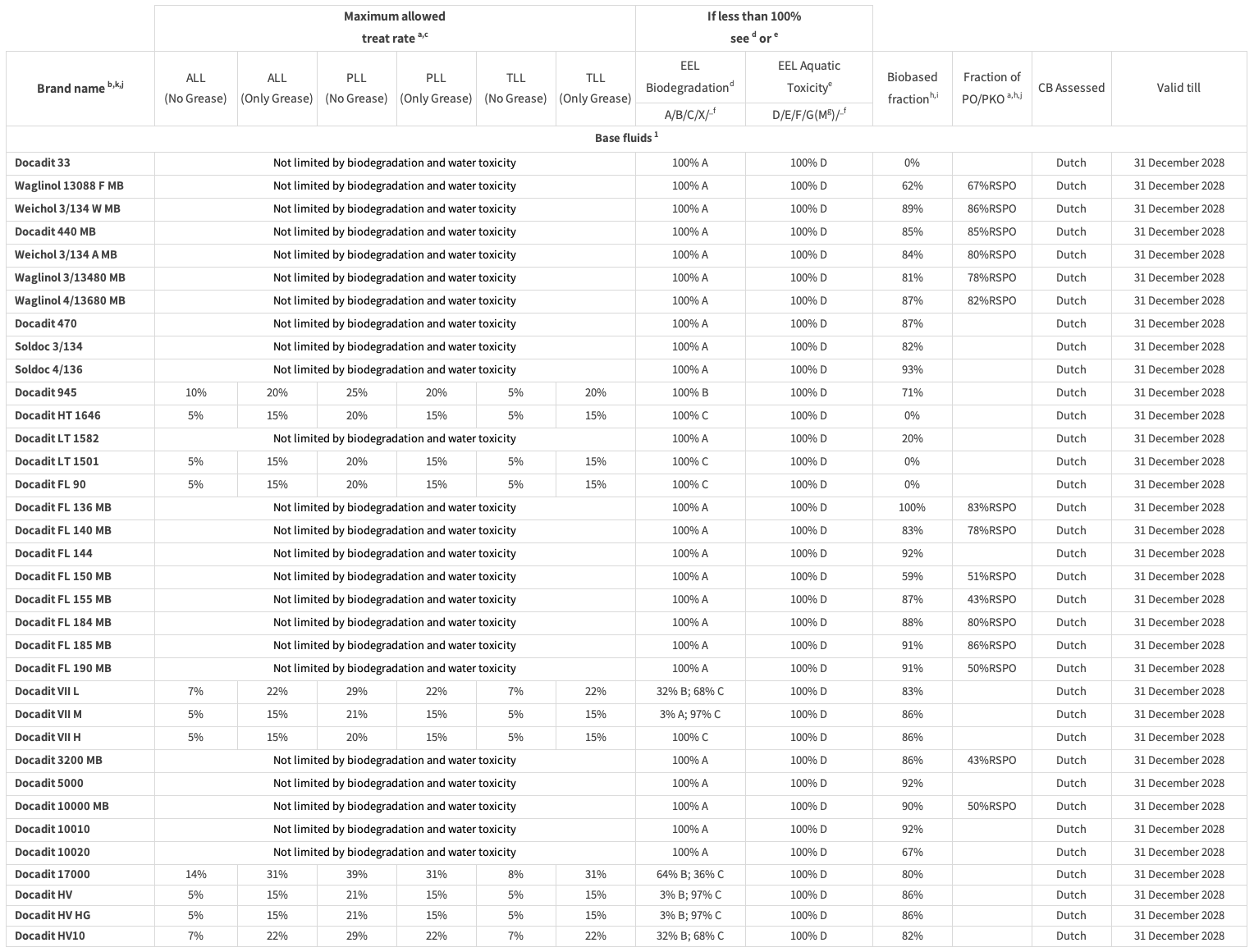

EU Ecolabel for lubricants has created a Lubricants Classification List (LuSC-list), where new criteria of 2018 revision, effective from 1st January 2019, included to the list different limits depending on total loss lubricants (TLL), partial loss lubricants (PLL) and accidental loss lubricants (ALL).

IQLubricants has some products included into the LuSC-list allowing to formulators directly use the products into their EAL formulas.

a) In case the treat rates and the fraction certified renewable material indicated on the LuSC-list and on the LoC are different, the most recent data are valid.

b) Substances that are excluded by EU decision 2018/1702/EU according to Criterion 1 and uncertified Palm oil or Palm Kernel oil are not present above 0.010% in the final composition.

c) The treat rate is usually set by the supplier before the assessment. Highest treat rate is applied in case the additive may possess different functions. The same or a lower treat rate for ANOTHER function does not alter its final EEL classification but in the ecolabel application form the correct function must be stated.

d) In case classification of the biodegradation has not been set at 100% but at a smaller fraction, e.g. 30%, then the total fraction with the specific classification is equal to the fraction of the treat rate applied by the applicant multiplied by the indicated fraction of the classification; e.g. 0.6% (applied treat rate) * 80% C (assessed fraction of biodegradation) is equal to 0.48% C. The value of 0.48% must be filled in in the application form for the brand name on biodegradation. The fraction not assessed on biodegradation is then automatically 0.60 – 0.48 = 0.12%.

e) In case the classification of the aquatic toxicity has not been set at 100% but at a smaller fraction, e.g. 30%, then the total fraction with the specific classification is equal to the fraction of the treat rate applied by the applicant multiplied by the indicated fraction of the classification, e.g. 0.6% (applied treat rate) * 80% E is total of 0.48% E for the brand name. The value of 0.48% must be used in the application form. The fraction unassessed on aquatic toxicity is then automatically 0.60 – 0.48 = 0.12%.

f) – means that it was not necessary to assess the substance(s) in the lubricant based on the stated maximum treat rate and the 0.1% limit in the ecolabel criteria for biodegradation, aquatic toxicity and renewability.

g) M = Multiplication factor for a substance that has an acute aquatic toxicity classified as very toxic (G).

h) Related to Criterion 4 of the EU decision 2018/1702/EU.

i) bio-based fraction must be larger than >25% based on valid C-14 method. If the bio-based fraction is not established yet but renewable fraction based on C-counting method is >50%, the entry will indicate n.d. indicating that the bio-based fraction has not been established yet.

j) The fraction of certified renewable ingredients required for optional criterion 8c is indicated here. If nothing is stated it means that the applicant has declared that no certified material has been used in the manufacturing process. If stated e.g. 50%RPSO it indicates that the applicant has stated that this is the complete fraction of Palm oil or Palm Kernel oil applied in the product process AND that the manufacturing company has a valid RSPO certificate at the time of application. Currently only an RSPO certification scheme is approved. If another certification scheme may have been approved later then the common abbreviation of that scheme will be indicated. If stated e.g. 50%NC (Not Certified)(Palm) it indicates that the company of the applicant has stated that 50% of the mass of the based fluid originates from palm oil or palm kernel oil, that this is the complete fraction of Palm oil or Palm Kernel oil applied in the product but the company cannot submit a valid RSPO certificate or any other relevant certificate. The applicant must buy in due time the appropriate amount of credits for the specific type of renewable material which is palm oil in this case.

k) In case of any modifications in the composition and/or in the CLP classification of the product, the supplier shall without delay notify the competent body, that assessed the product concerned.

l) Only in case the name on the LuSc-list or LoC matches exactly the tradename on its corresponding SDS the treat rates and assessments are valid.